High Standard Artwork Process

-

Production Capacity

20 sets of automated production machines for dental floss with an annual output of 800 million pieces bottles.

2 mouth spray production lines with an annual output of 5.5 million bottles.

2 mouthwash production lines with an annual output of 8 million

2 production lines for teeth whitening products and other products

Technological

processWith a GMP-certified 100,000-level purification workshop of 5000 square meters, the current average daily production capacity of dental floss sticks has reached 2.2 million, and the annual production ...

-

Production Capacity

目前牙线棒日均产能达到220万支,年产能达到6.6亿支左右;漱口水日均产能30000瓶,年产能达到800万瓶左右;口喷日均产能20000瓶,年产能达到550万支左右。产能仍在继续提升,尤其是牙线棒的年产能计划在短期内提升至15亿支。目前牙线棒日均产能达到220万支,年产能达到6.6亿支左右;

漱口水日均产能30000瓶,年能达到800万瓶左右;口喷日均产能20000瓶,年产能达到550万支左右。产能仍在继续提升,尤其是牙线棒的年产能计划在短期内提升至15亿支。

Technological

Technological

process目前牙线棒日均产能达到220万支,年产能达到6.6亿支左右;漱口水日均产能30000瓶,年产能达到800万瓶左右;口喷日均产能20000瓶,年产能达到550万支左右。产能仍在继续提升,尤其是牙线棒的年产能计划在短期内提升至15亿支。

-

Production Capacity

目前牙线棒日均产能达到220万支,年产能达到6.6亿支左右;漱口水日均产能30000瓶,年产能达到800万瓶左右;口喷日均产能20000瓶,年产能达到550万支左右。产能仍在继续提升,尤其是牙线棒的年产能计划在短期内提升至15亿支。目前牙线棒日均产能达到220万支,年产能达到6.6亿支左右;

漱口水日均产能30000瓶,年能达到800万瓶左右;口喷日均产能20000瓶,年产能达到550万支左右。产能仍在继续提升,尤其是牙线棒的年产能计划在短期内提升至15亿支。

Technological

Technological

process目前牙线棒日均产能达到220万支,年产能达到6.6亿支左右;漱口水日均产能30000瓶,年产能达到800万瓶左右;口喷日均产能20000瓶,年产能达到550万支左右。产能仍在继续提升,尤其是牙线棒的年产能计划在短期内提升至15亿支。

Strict Disinfection Protection

-

Passage

Passage -

Changing shoes

Changing shoes -

Hands disinfection

Hands disinfection -

Changing clothes

Changing clothes

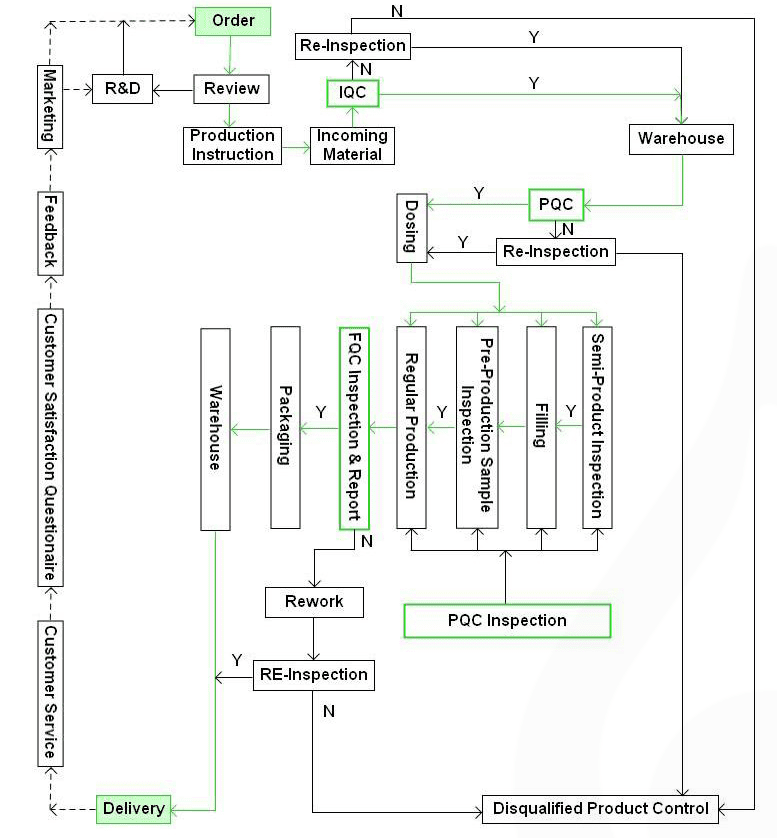

Multiple inspections, Assured products

经过多重检验,让消费者真正使用到高品质、无菌卫生、安全的口腔护理产品。

经过多重检验,让消费者真正使用到高品质、无菌卫生、安全的口腔护理产品。

protection

GMP certificated Cleansing workshop

-

Air shower

Air shower -

Production

Production

GMP 100,000 Grade Cleaning Workshop

Sterile materials in and out of the workshop

Special material entry and exit channels, raw materials, packaging materials and other materials entering and leaving the workshop must be sterilized by ultraviolet, ozone, etc. before entering the workshop.

Special area for unpacking and disinfecting packaging materials to prevent bacteria and dust from entering the workshop.

workshop

-

Unpacking

Unpacking -

Raw material disinfection

Raw material disinfection -

Raw material air shower

Raw material air shower -

Entering the feeding room

Entering the feeding room

-

Unpacking

Unpacking -

Raw material disinfection

Raw material disinfection

经过多重检验,让消费者真正使用到高品质、无菌卫生、安全的口腔护理产品。经过多重检验,让消费者真正使用到高品质、无菌卫生、安全的口腔护理产品。经过多重检验,让消费者真正使用到高品质、无菌卫生、安全的口腔护理产品。经过多重检验,让消费者真正使用到高品质、无菌卫生、安全的口腔护理产品。经过多重检验,

Quality Control Throughout the process

Multiple inspections, Multiple guarantees

Standardized laboratories and advanced precision testing instruments conduct testing in strict accordance with relevant standards for each batch of products. Strict QC testing is carried out in all links from raw material procurement, sample proofing, personnel and logistics in and out of the workshop, manufacturing production, semi-finished and finished products, finished product storage, and finished product samples to ensure 100% high quality of our products.

control